Design to Production - PlayLight

Versatile and modular, Play Light requires interaction from the users and it is made to embrace different needs.

Play Light was one of the products we designed and launched in our Design Studio (100 pcs produced - 9k€ Revenue).

We were responsible for the entire product development, from the concept to the production, distribution and advertising. On my Medium profile you can find more about this experience:

- the negotiation art

- the team working

- the value of iteration

- marketing evaluation

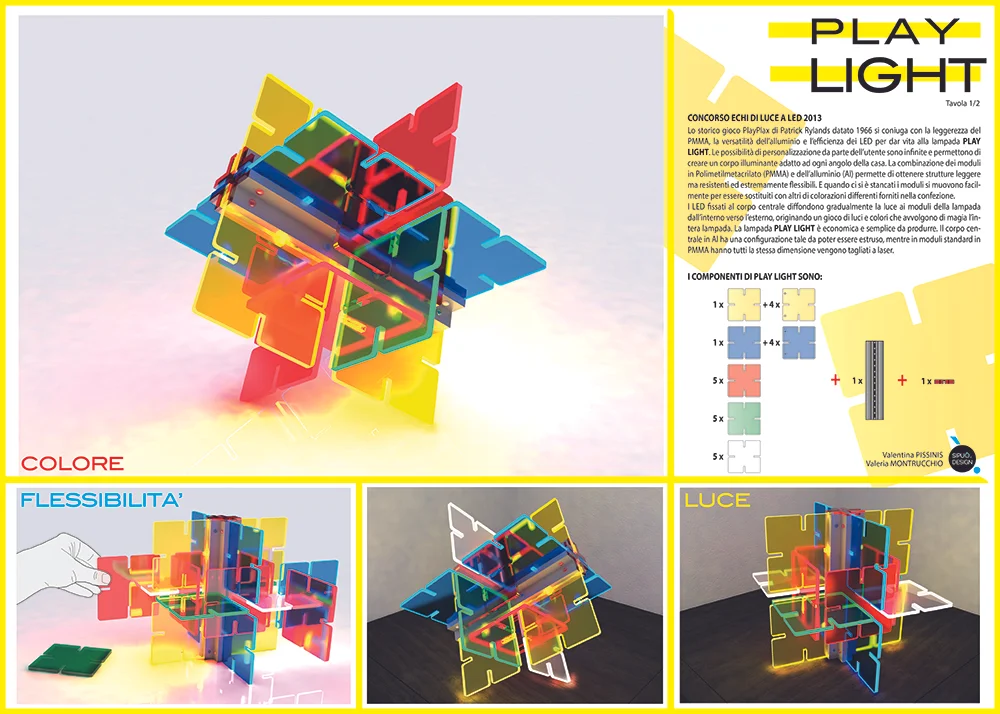

This desk lamp combines together the PMMA's lightness and the LED’s efficiency. It is formed by 18 coloured blocks of PMMA that can easily assume different positions to create the most suitable form for every house.

What: Concept development, Prototype, Production, Distribution, Marketing & Advertising

How: Rhinoceros, Autocad, 3D Studio MAX, Illustrator, Photoshop | Production: Laser Cut (PMMA Material)

When: 2013, 5 months

Concept Development

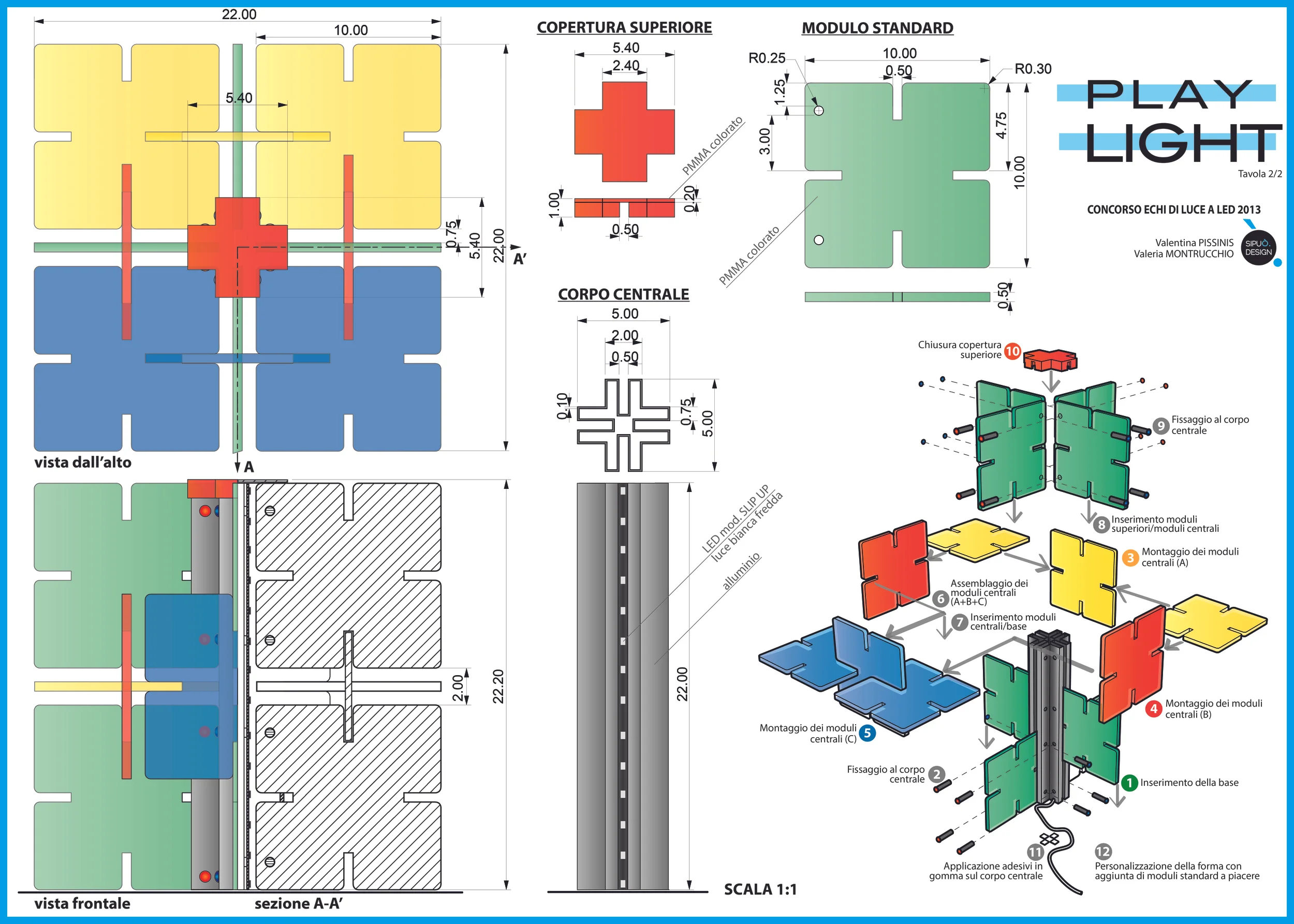

We started with sketches and then we put together a presentation and a technical board in order to understand feasibility, viability and desirability of the new concept.

Since the lamp resulted successful in this first analysis, we started to contact suppliers and manufacturers to plan our business and make a cost analysis.

Several prototypes and quotations later, we gave the green light to a local supplier who was responsible for both the PMMA laser cuts and the electronic system.

One of the initial prototypes, on which we based the following production.

Prototype

During the prototyping phase, we had a couple of critical issues that needed a prompt action.

The first one was when we discovered that the glue the supplier was using wasn’t strong enough and the LEDs were falling apart. Luckily we spotted that on time and he was able to solve the issue using a different glue.

Then, when all the lamps were finished and already in their boxes, we decided to randomly check few samples. We suddenly realized that one every three lamps couldn’t be mounted because the pieces had 0.5 mm difference with the original dimension we designed. With the success of the project in jeopardy, we had to lean on our ability to negotiate.

Google Form, available here

Users Test & Questionnaire

Together with the lamps, we distributed a link to a Google Form with the intent of gathering possible suggestions for future realises and to assess the level of satisfaction of the client. That was a quick and simple way of contacting our customers and to obtain analytic data.

Marketing & Distribution

In order to differentiate the distribution we opted for on-line and in store selling. We sold the lamps in two design shops in Turin that promotes young designers, two furniture shops, one small shops owned by a local architecture firm. Regarding the online distribution, we contacted design market in Italy and internationally located.

Through a dedicated Facebook page we advertised the lamp and contacted our public. We made sure to upload new posts every week and to refresh the gallery with new pictures and comments from our buyers.

To promote the product we sent a newsletter to our followers with updates every two weeks, we took part to two design weeks in Turin and to a shop inauguration where we managed to use our lamp as part of the set up.

What would we change if we had to do it again

Now that we know how to deal with all the steps of the process, I'm sure we would have a quicker timeline from the concept to the launch.

By learning from our experience with the supplier, we'd try to avoid unpleasant discoveries, by including more terms before closing the deal (e.g. we'd make sure that the prototype they submit will match 100% the final products they'll produce) and we'd be more careful when analysing their offer.